Qingdao Kunyuan Machinery Co.,Ltd.

Address: Mingguan Road No.729 Huangdao area Qingdao china

Phone:

13506429902

13963992990

Tel: 0532-86151277

Fax: 0532-89050585 86152277

Technical Advisory: 13506429902

E-mail: [email protected]

[email protected]

PRODUCT CLASS

Aluminum profile through shot blast..Marble Shot Blasting MachineH Type Section Steel Shot Blasting ..Gear Shot Blasting MachineIn Addition To Dust EquipmentsSteel Pipe Inner Wall Shot Blasting..Steel Pipe Outer Wall Shot Blasting..Big Steel Structure Shot Blasting M..Spring Shot Blasting MachineHoist Hook Shot Blasting MachineSteel Pretreatment Complete lineSteel Belt Shot Blasting MachineRebar Shot Blasting MachineSprayed The Pill MachineRoller Shot Blasting MachineRolling Drum Shot Blast Cleaning Ma..Vertical Steel Plate Shot Blasting ..Portable Shot Blasting MachineApron Tumblast Shot Blasting Machin..Anchor Chain Shot Blasting MachineWear-resistant Sparc-partsThe Blast WheelSpraying Sand RoomGas Cylinder Inner Wall Shot Sprayi..Gas Cylinder Outer Wall Shot Blasti..Tnclined Rolling Drum Shot Blasting..Bent Axle Shot Blasting MachineResin Sand EquipmentsCar Shot Blasting MachineNet Belt Shot Blasting MachineRubber Apron Tumblast Shot Blasting..Small Steel Pipe Inner Wall Shot Sp..Small Steel Pipe Outer Wall Shot Bl..The Tach Derrick Chain Cleaning Sho..Sand Processing EquipmentsHook-turntable Shot Blasting Machin..Trolley Shot Blasting MachineSucker Rod Shot Blasting MachineRotary table blasting machineSteel plate profile surface cleanin..

CONTACT US

Company Address: No.427 lingqueshan road huangdao area Qingdao

Postal Code: 266400

Phone: 13506429902

13963992990

Tel: 0532-86151277

Fax: 0532-86152277

Technical Advisory: 13506429902

E-mail: [email protected]

News

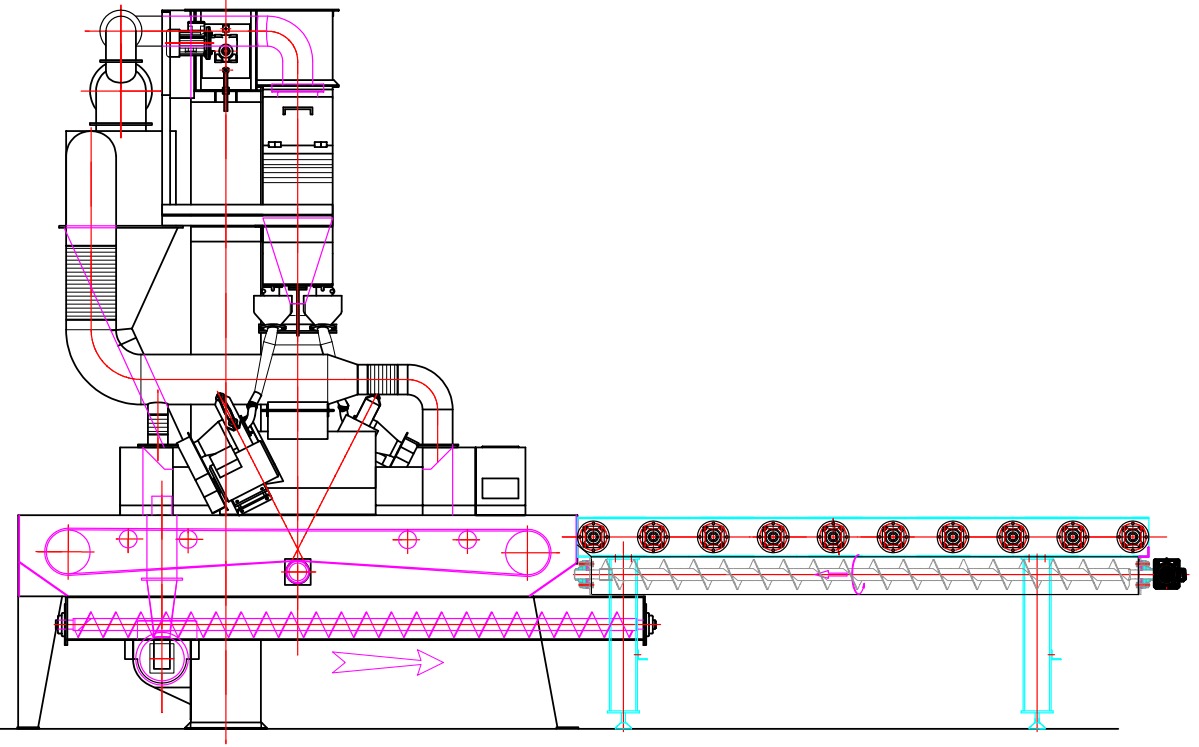

Continuos in-line rubber Belt Work Conveyor Blast Cleaning Machine

The online rubber crawler through-type shot blasting machine is designed for small aluminum alloy parts, thin-walled aluminum alloy parts, long aluminum alloy parts and other aluminum alloy parts that are collision and volatile. It has the advantages of high automation, good cleaning effect and high production efficiency. At the same time, it is also applicable to workpieces made of stainless steel, carbon steel and other materials that are collision and volatile.

working principle:

Manual loading → shot blasting → output roller table → shot collecting screw to collect scattered steel shot → manual unloading

Structural features:

The shot blasting room consists of the front auxiliary room, the upper sand blasting room, the rear auxiliary room, the shot blowing room, the lower chamber body, the delivery roller table, the shot receiving screw, and the shot material circulation purification system

And dust removal system.

The cleaning chamber body is welded by steel plates. The chamber is lined with 13Mn protective plate. The special wear-resistant nut is fixed, which is resistant to bullet impact and easy to install and replace. Multi-layer polyurethane sealing curtain is set at the inlet and outlet of the chamber to prevent the projectile from flying out of the chamber.

2. Blastwheels

The shot blasting chamber is equipped with 2 sets of shot blasters to ensure that the passing aluminum material is treated with one-time sand. The shot blaster assembly is composed of shot blaster, motor, etc.

The cantilever centrifugal shot blaster used in this machine has the advantages of high efficiency, convenient installation and maintenance, small space occupation, and can be set to rotate left and right. The blade is fixed by centrifugal force during rapid rotation, without any fixed fixture, and is easy to disassemble.

Workpiece conveying system adopts wear-resistant rubber conveyor belt to ensure that aluminum alloy parts will not be scratched; The transmission system is driven by the NMRV shaft-mounted reducer,It is also equipped with frequency converter for speed regulation to ensure good shot blasting effect.

4. Elevator

Bucket elevator is composed of NMRV reducer, upper and lower rollers, conveyor belt, hopper, closed barrel and tensioning device. The feed port of the bucket elevator is connected with the transverse screw conveyor, and its discharge port is connected with the separator.

There is an access door on the cover of the elevator, which can repair and replace the hopper. Open the door cover on the lower cover to repair the lower drive and eliminate the bullet blockage at its bottom.

This machine adopts flat belt drive. During operation, the hopper fixed on the conveyor belt scrapes up the shot material at the bottom of the elevator and receives the shot material flowing from the transverse spiral conveyor. Then, driven by the elevator motor, the shot material is conveyed to the top of the elevator, and finally, the shot material is dropped by centrifugal gravity, and the shot material is fed into the separator spiral.

In order to ensure that the conveyor belt does not slip during operation, the drum is made into a squirrel-cage type, which not only improves the friction between the lifting belt and the pulley, avoids the slipping of the old smooth pulley, but also reduces the preload of the lifting belt, which helps to extend the service life of the lifting belt.

At the same time, the hoist is equipped with a set of tensioning device. When the belt is loose, the adjusting bolts on both sides of the upper part of the hoist should be adjusted to tighten the belt.

5. Separator

This machine is equipped with a full-curtain shot sand separator. The shot material flows into the spiral of the separator from the bucket elevator. Under the action of the spiral and the adjusting plate, the shot sand mixture is uniformly distributed along the separator, thus forming a full flow curtain state, and enters the following air separation stage. At this time, the dust remover fan draws air through the separator air extraction hole to effectively separate the steel sand and metal debris, scale debris, broken steel sand and dust. The large particle waste flows out of the separator shot material overflow port and is separated and deposited on the screen. The small shot material and dust flow out of the waste outlet, and the qualified shot material enters the shot material bin for circulation.

Adjusting the gap between the vertical and horizontal adjustment baffles of the separator can change the thickness and movement track of the distribution layer, and with the adjustment of the adjustment baffles in the separation zone, a good separation effect can be achieved. Working principle of separator

The screw conveyor is located at the bottom of the sand surface treatment room. When working, the screw shaft is driven by the NMRV reducer to rotate, and the shot material is conveyed to the discharge port and flows into the transverse screw conveyor.

7. Rotary sieve

A rotary sieve is installed at the feed inlet of the elevator, which can effectively screen out large particles of impurities and ensure the smooth operation of the pellet circulation system without jamming,Damage to equipment.

8. Cyclone body

The dust-containing air flow generated in the process of shot blasting enters the cyclone body through the pipeline. The dust-containing air flow forms a cyclone in the cyclone body, and the large particles of dust settle down. The gas with small particles of dust enters the filter through the pipeline.

9. Filter

The filter is composed of shell, fan, ash collection hopper, pulse valve, pulse controller, filter cartridge, air bag, etc. Filter cartridge is made of polyester long fiber.Non-woven fabric flame retardant+PTFE film covering material, dust emission concentration is less than or equal to 20mg/m3. The Venturi pulse back blowing soot cleaning system has the advantages of low filtration wind speed, high filtration accuracy and good soot cleaning effect

Main technical parameters:

Processing air volume 5000m3 /h

Filter cartridge size Φ360×1000mm

Filtering area of single filter cartridge 16 m3

Processing air volume of single filter cartridge 600m3/min

Filtration velocity ≤0.8m/min

Blowback compressed air pressure 5kg/m2~7kg/m2

Blowback interval 2~3min/次

Blowback period 20min

Blowback time 2~3s

Number of filter cartridges 4

10. Electrical system

The electric control system is composed of control cabinet, touch screen and cable, and adopts Siemens PLC, touch screen and electrical components.